Aramiro Ahu Whenua Trust

CASE STUDY

Water Storage

Securing water sovereignty

A JOURNEY TO SUSTAINABLE DEVELOPMENT AND SELF-SUFFICIENCY

The Aramiro Ahu Whenua Trust in Waitetuna, run by General Manager Brett Te Whare, started a plan five years ago to take their land, which has 1,700 shareholders, from underperforming to thriving. The plan included beginning to harvest a plantation of pine trees, planting more than 70,000 natives and fencing waterways on the sheep and beef farm.

As part of their plan they are also considering a native plant nursery and other ventures that will secure a sustainable future for the property, alongside farming and forestry. The Trust provides primary industry training for local tamariki with the vision that they will work on the block in future years.

A key factor in achieving a sustainable and self-sufficient future for Aramiro Ahu Whenua Trust was water security.

The property has a bore that currently supplies water to the farm and feeds a small settlement of homes and the neighbouring marae but a feasibility study identified this was a limited resource that restricted future growth on the property.

With plans to build the nursery and allow for future increases in the size of the local community, the Trust needed a reliable source of water storage that would serve their present requirements and provide protection and resilience in years to come.

Brett had spoken to local farmers in the region who suggested Tauranga business, KlipTank, could provide the water storage solution he needed.

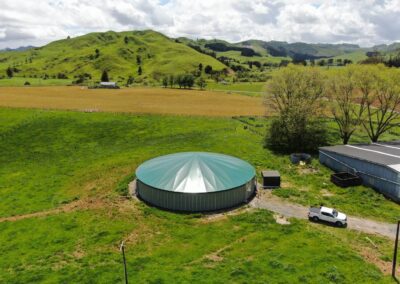

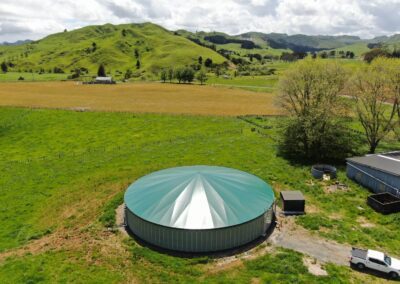

He applied for an infrastructure grant for the supply and installation of a 1,000m³ roofed KlipTank. The tank is filled with rainwater from the existing farm buildings and the 400m² roof area of the tank itself is used for rain harvesting too.

“We’ve got a 1,000 cubic metre capacity tank with a roof on top. We had some adjacent buildings that the water was just running off. A woolshed, an implement shed and a shearers’ quarters and none of them had good roofs or guttering. So part of the funding allowed us to re-roof one of the buildings and put gutters on them, and we piped them all to the tank.”

Brett said working with KlipTank had been a very positive experience. “Their communication is awesome. We got an independent contractor to do the site prep and there was good communication with them about what KlipTank’s needs were.”

“Right through from the sales team to the construction team to the service afterwards, we were very happy with KlipTank. There’s a couple of things that we had challenges with during construction, but they were really well-communicated and quickly resolved. I deal with a lot of contractors through the work we’re doing, and KlipTank’s right at the top of our list in terms of providers and suppliers.”

The Trust considers the tank as providing water sovereignty. “We’re in charge of everything we do, if we have our own strategy and a plan to make it happen. The water is the key component, without water our industry doesn’t survive. We just had to have a storage option that fitted our future needs.”

“The whole idea of water storage (probably partly because of the three waters discussion) has become more on the radar for people. They’re starting to think about not just relying on bores etc., and about how they can make sure that they’re looking after themselves. In the past water’s been viewed as an unlimited resource, it’s not unlimited.”

The Trust is also looking at options for recycling the water from the tank. “You’ve got to have more than one bite of water, otherwise it’s a waste in our view.”

Brett hopes in future to see water storage, as a requirement to issuing a building consent on a new home, rather than just plumbing into the town supply.

Impressed with the process and final result after working with KlipTank, Brett is planning on ordering another KlipTank to store water for hydro power.

BRETT TE WHARE

Aramiro Ahu Whenua Trust

Waitetuna

What other customers have to say about their KlipTank

Meet the team

Kim HendersonDirector

Kim co-founded KlipTank in 2009 and become owner in 2021, after returning to New Zealand from the United States.

For 26 years overseas, Kim worked in the oil and gas industry across the Middle East and US.

His forte is starting greenfield units, which he did for his own flexible hydraulic hose business in the Middle East, Turkey, Singapore, the United States, Oman and China. His grown-up children still reside in the United States.

Kim returned to New Zealand to be closer to extended family and is now involved in the day to day running of KlipTank, with big plans for the expansion of the business.

From KlipTank’s home in Tauranga, he is now looking forward to guiding the company’s growth in the area of water security and providing water storage solutions for fire safety, potable water, horticulture and waste-water.

A redesign of KlipTanks products and manufacturing processes since 2021 has also allowed for flat packing of the tanks into containers for export.

He is extremely proud of what the hardworking KlipTank team has achieved and is looking forward to recruiting more great people.

Outside of work he has a passion for motorcycles, boats, and muscle cars and is a firm believer that the correct number of toys you should own, is one more than you have.

Ruan MeyerGeneral Manager

Ruan and his family moved to New Zealand from South Africa 5 years ago, bringing with him extensive experience in mechanical engineering and a proven track record in completing projects on time and within budget.

He is currently the General Manager at KlipTank, recently promoted from being Operations Manager where he still manages the day-to-day operations of KlipTank and leads the team. He is focussed on seeing projects through to completion and working in unison to achieve KlipTank’s short and long-term goals.

Ruan started his career as a Fitter & Turner tradesperson at a power station in South Africa before studying for a national diploma in mechanical engineering.

He then moved to Malvern Engineering Works in Johannesburg as an estimator and project co-ordinator, and later worked as production manager, manufacturing mine process equipment. He then became project and maintenance manager for Mertech Marine in Cape Town, a company which manages ships that retrieve redundant telecommunications cables & equipment from the seabed and mechanically disassemble & recycle the materials.

Since moving to New Zealand, he’s worked for HCD flow conveying, Baytext as Aluminium WS Engineering Supervisor, PFS as PE doing ASME pressure vessel and piping projects and Fabworx engineering PM including leading the Structural project to install 80 tonnes of steel at the new Wai Ariki Hot Springs and Spa in Rotorua.

Ruan is a family man with two children and enjoys weekends on the beach, in the backyard and biking or walking local trails. He has found a great network of other ‘Saffas’ in the Bay, including close friends who have become like Kiwi family.

Ian JamiesonSales Manager

Ian Jamieson joined KlipTank 10 years ago, bringing with him an extensive sales and business background in the IT and mechanical engineering industries. He has owned his own businesses in both fields and has an extensive formal education in engineering, including a degree in process engineering.

Ian’s wide ranging, technical skill set lends itself well to KlipTank’s philosophy of solving problems for its customers and being solutions-focussed.

He particularly likes working with New Zealand’s vital dairy industry and has found farmers to be excellent businesspeople who display incredible resilience.

He enjoys building strong relationships with his customers and getting to know their businesses – including their storage requirements – which are often planned years in advance.

He also has a Farm Dairy Effluent Design & Management Certificate from Massey University, allowing him to assist farmers with dairy effluent system design and storage calculations for consent purposes.

Outside the office, Ian is a self-confessed motorsport nut – coming from a long line of engineers with petrol in their veins. He enjoys motorsport engineering, riding his vintage motorbike and motocross. He also plays music, loves to travel and enjoys a good wine - particularly French.