Water Storage

KlipTank specialise in water storage solutions for drinking water, rain harvesting, waste water, irrigation and stock drinking water.

Agriculture

Above ground dairy effluent storage is the environmentally friendly and safe way to store your effluent prior to irrigating to pasture. Our great looking tanks come in a range of volumes to suit.

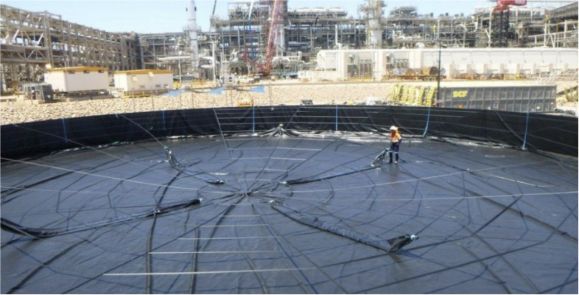

Industrial

Kliptanks can be used for the treatment, storage and processing of all types of water and industrial waste assisting you in creating a more environmentally safe product for discharge or reuse.

Horticulture

KlipTanks serve as an ideal water storage solution for irrigation and frost protection for crops and can be customised as an open-top tank with a capacity of up to 6 million litres.

Fire water storage

KlipTanks are a great fire water storage solution across various industries. Additionally, as suppliers of Tank Vision steel bolted tanks, we offer a broader range of tank options including square and round tanks suitable for basement level buildings.

Waste water storage

KlipTanks can be customised to serve as tickle filters and are suitable for both municipal and industrial wastewater storage, including dairy, wine, meat, and beneficiation processes.

Our patented design delivers flat-packed tank components direct to site

- Customise the tanks to store water and effluent

- Irrigate your farm with recycled wastewater (more nutritious for soil)

- Minimise wastage of water

- Harvest rainwater

- Made with reusable materials

- Personnel training for optimum use

- Relocation of the tank if needed

- Installation with minimal prep

- 100% transparent pricing

- Customisable inlets and outlets

Above ground storage tanks

Functional, practical, multi-usage water, effluent and industrial liquid storage tanks

Our process

01

Design and Engineering

Our third-party engineers are tasked to certify KlipTank products to meet New Zealand seismic and construction requirements.

KlipTank’s are designed based on the following:

-

- The site must have allowable ground bearing capacity ranging from 30-60kPa depending on tank height. Ultimate ground bearing capacity ranging from 90-180kPa depending on tank height.

- NZ Climatic & Seismic standards for wind, earthquake and rain.

- Importance Level 1 Structure as defined in AS/NZS1170.0:2004.

- Structural design loads are based on a 25-year design life.

Design has been made in accordance with the New Zealand Building Code Compliance Documents:

- AS/NZS1170.0:2002 – Parts 1,2,3,4, & 5 (Structural design actions).

- NZS3404:1997 (Steel Structures Standard).

- NZS3101:2006 (Concrete Structures Standard).

- NZS3106:2009 (Design of Concrete Structures for the Storage of Liquids).

- AS/NZS1665:2004 (Welding of Aluminium Structures).

- AS/NZS1554.1:2014 (Structural Steel Welding).

Materials

KlipTanks are a composite tank design that utilise the advantages of a variety of construction materials to make lightweight yet robust and durable storage tanks.

- Walls: HDPE Panel with UV Inhibitors (thickness 4.5mm) with PVC extruded upright.

- Top and Bottom Rings: Grade 6106 aluminium.

- Wire Ropes: Galvanised wire rope with stainless steel swage ends and bronze connecting turnbuckles are customised according to the specific storage requirement.

- Liner: Liners are customised according to the specific storage requirement.

- Roof Cover: Available in UV block out, stabilised PVC cover and hard roof cover options.

- Fittings: Alloy plate fittings with galvanised steel nozzle at size specified. Glass-reinforced Nylon bulkhead fittings (Hansen) and stainless fasteners.

02

Site preparation and Soil testing

Preparing the site for a KlipTank installation is a crucial step to ensure optimal performance and longevity of the tank.

KlipTanks are designed to be low-maintenance and do not require a concrete foundation in most cases. Instead, they require a site base with allowable ground bearing capacity ranging from 30-60 kPa depending on tank height. Ultimate ground bearing capacity ranging from 90-180kPa depending on tank height.

Consider this: the ground bearing required for a KlipTank is less than the pressure exerted by a bicycle or a woman wearing high heels. This demonstrates the minimal impact on the ground.

Before installation, the grass and topsoil should be stripped back to the subsoil, the subsoil compacted and soft spots removed and filled. A layer of approximately 60mm of crusher dust or a similar material, without sharp edges, should be applied to prepare the site.

Additionally, our installation team will cover the area between the tank wall and liner with this material, which should be applied every two metres around the perimeter.

For detailed guidance on site preparation, please refer to our Site Preparation document available for download in the Resources section of our website.

We understand that site preparation is a critical step in the installation process. Therefore, we recommend consulting with our KlipTank Installation Manager or your Sales Engineer before your contractor begins any work. This will ensure that the site is properly prepared and ready for the installation of your KlipTank.

*Please note polished sand is not an acceptable finishing layer as it will wash away.

03

Council Compliance

District Council Requirements – Building Consent

At KlipTank, we understand that navigating the District Council requirements for building consent can be overwhelming. That’s why we work closely with councils throughout New Zealand to stay updated on their specific regulations for each zoning.

We will handle the entire building consent process on your behalf, taking the hard work away from you. Our team is well-versed in the unique questions and requirements that councils may have, enabling us to swiftly complete the necessary forms.

It is important to note that councils may request a foundation/location inspection as well as a final inspection. Rest assured, KlipTank will take care of coordinating these visits between you, the purchaser, and the council. Once the tank construction is completed and the final inspection has passed, we will apply for the code compliance certificate. This ensures that your KlipTank complies with all the relevant local and regional regulations.

With our expertise and proactive approach, we make the building consent process as seamless as possible, ensuring that your KlipTank installation meets all the necessary requirements set by the District Council.

Resource Consent

In accordance with the rules outlined in the District Plan, obtaining a resource consent may be necessary, depending on the specific requirements of your council.

If required, KlipTank can assist you with completing simple resource consent applications. However, for more complex applications, we may recommend that you directly engage with your local resource consent management services for the best outcome.

Please note that a building consent typically takes approximately 20 working days to process from the date of lodgement and acceptance. However, it is important to allow for an additional approximate six weeks to obtain a resource consent, considering the necessary time for this process.

04

Installation

Prior to dispatching our install team, KlipTank may conduct an inspection of your prepared site. This inspection ensures that the site is of the correct size, properly situated, level, and ready for installation.

We understand that delays can be costly. If the installation is postponed due to an inadequately prepared site, a per hour labour rate will be applied to rectify the site.

Once the manufacturing process is complete, KlipTank will transport your tank and liner to the site, fully prepared for installation.

Depending on the size of the tank, the installation process typically takes between three to six days on-site. Our experienced team will efficiently and effectively carry out the installation to ensure a timely completion.

Upon completion of the installation, our dedicated KlipTank Sales Engineer will initiate contact with the council to organise a final inspection. A ‘Passed’ inspection is required to accompany the application for the code compliance certificate.

From site preparation to final inspection, our team is committed to providing a hassle-free experience and ensuring compliance with all necessary standards and regulations.

05

Maintenance and Warranties

Once your installation is complete, we will equip you with a detailed maintenance manual and a list of regular checks. Our guidance will ensure that you can easily undertake the necessary maintenance tasks to keep your KlipTank running smoothly.

We offer maintenance contracts that guarantee seamless and continued care for your tank and fittings. Our contracts cover maintenance for pumping systems, pipe work, and pressure testing, leaving you with peace of mind and more time to focus on what matters most.

As part of our maintenance contracts, we provide customised training sessions for your staff members. Our experts will thoroughly train your team on the operation of the KlipTank in your specific environment, ensuring that they have the knowledge and skills to maintain the optimal performance of your system. With our training, you can confidently rely on your staff to handle any maintenance needs that may arise.

With our support and maintenance contracts, you can be confident that your KlipTank will consistently operate at its best. Contact us today to learn more about how our maintenance services can provide you with peace of mind and long-lasting performance.

Ready to get started?

Contact us to discuss your requirements

Meet the team

Kim HendersonDirector

Kim co-founded KlipTank in 2009 and become owner in 2021, after returning to New Zealand from the United States.

For 26 years overseas, Kim worked in the oil and gas industry across the Middle East and US.

His forte is starting greenfield units, which he did for his own flexible hydraulic hose business in the Middle East, Turkey, Singapore, the United States, Oman and China. His grown-up children still reside in the United States.

Kim returned to New Zealand to be closer to extended family and is now involved in the day to day running of KlipTank, with big plans for the expansion of the business.

From KlipTank’s home in Tauranga, he is now looking forward to guiding the company’s growth in the area of water security and providing water storage solutions for fire safety, potable water, horticulture and waste-water.

A redesign of KlipTanks products and manufacturing processes since 2021 has also allowed for flat packing of the tanks into containers for export.

He is extremely proud of what the hardworking KlipTank team has achieved and is looking forward to recruiting more great people.

Outside of work he has a passion for motorcycles, boats, and muscle cars and is a firm believer that the correct number of toys you should own, is one more than you have.

Ruan MeyerGeneral Manager

Ruan and his family moved to New Zealand from South Africa 5 years ago, bringing with him extensive experience in mechanical engineering and a proven track record in completing projects on time and within budget.

He is currently the General Manager at KlipTank, recently promoted from being Operations Manager where he still manages the day-to-day operations of KlipTank and leads the team. He is focussed on seeing projects through to completion and working in unison to achieve KlipTank’s short and long-term goals.

Ruan started his career as a Fitter & Turner tradesperson at a power station in South Africa before studying for a national diploma in mechanical engineering.

He then moved to Malvern Engineering Works in Johannesburg as an estimator and project co-ordinator, and later worked as production manager, manufacturing mine process equipment. He then became project and maintenance manager for Mertech Marine in Cape Town, a company which manages ships that retrieve redundant telecommunications cables & equipment from the seabed and mechanically disassemble & recycle the materials.

Since moving to New Zealand, he’s worked for HCD flow conveying, Baytext as Aluminium WS Engineering Supervisor, PFS as PE doing ASME pressure vessel and piping projects and Fabworx engineering PM including leading the Structural project to install 80 tonnes of steel at the new Wai Ariki Hot Springs and Spa in Rotorua.

Ruan is a family man with two children and enjoys weekends on the beach, in the backyard and biking or walking local trails. He has found a great network of other ‘Saffas’ in the Bay, including close friends who have become like Kiwi family.

Duheine MyburghMarket Manager - Water

Duheine is a qualified hydrogeologist and joined the KlipTank team in 2021, taking on the newly-established role of Market Manager - Water.

He is focussed on the export side of the KlipTank business, particularly in the Pacific Islands, where complex logistics and limited infrastructure make KlipTank products the perfect solution to rainwater harvesting.

He oversees the tender submission process on large offshore water storage projects and is currently managing a 3-year project to deliver 280 water storage KlipTanks to the Marshall Islands.

Duheine also manages the fire water storage market for KlipTank in New Zealand. Some of KlipTank’s end users include the Warehouse Group and NASA, to name a few.

Originally from South Africa, he spent 10 years in the mining industry working in the diamond, coal and coalbed methane gas commodities.

Duheine and his family moved to New Zealand in 2018, where he joined Wellington Water as a Senior Engineer in the drinking water team. Keen to escape the wind, they moved to Tauranga in 2021, where his extensive experience in water management made KlipTank a great fit.

To relax, Duheine enjoys fishing and spending time with his wife and three young children.

Frequently asked questions

Do I need a concrete pad for a KlipTank?

No, you don’t. Most of our tanks require a ground bearing of 90kPa unless we specify otherwise. Generally, you would remove the topsoil down to a hard base then build the tank pad with aggregate (GAP 65 or rotten rock for example) and a 60mm compacted layer of crusher dust or fines.

Who can do my site preparation?

You have the option to do it yourself or hire a local contractor. We provide detailed instructions to make the process as easy as possible, and our Installation Manager is available for advice at any time.

Can a KlipTank be used on soft or unstable ground like Peat?

Absolutely. KlipTank specialises in these situations. Our tanks are engineered to withstand subsidence and movement. Please note that customers will need to sign a Waiver at the time of entering into an Agreement, acknowledging the need for extra monitoring and the possibility of additional costs for site preparation and maintenance.

Do we need to get a building consent for our KlipTank?

Yes, according to the NZ Building Code, any structure holding more than 35,000 litres requires a building consent. KlipTank will handle all the paperwork and lodge it on your behalf. We charge a small admin fee for this service and will pass on the Council’s charges at the end of your installation. This process ensures that a certified Engineer signs off on the tank design and conducts site-specific structural calculations for seismic, wind, and snow loadings.

What are KlipTanks made from?

KlipTanks are made from high-quality materials sourced from New Zealand.

- Walls: HDPE Panel with UV Inhibitors (thickness 4.5mm) with PVC extruded upright.

- Top and Bottom Rings: Grade 6106 aluminium.

- Wire Ropes: Galvanised wire rope with stainless steel swage ends and bronze connecting turnbuckles are customised according to the specific storage requirement.

- Liner: Liners are customised according to the specific storage requirement.

- Roof Cover: Available in UV block out, stabilised PVC cover and hard roof cover options.

- Fittings: Alloy plate fittings with galvanised steel nozzle at size specified. Glass-reinforced Nylon bulkhead fittings (Hansen) and stainless fasteners.